وصف المنتج:

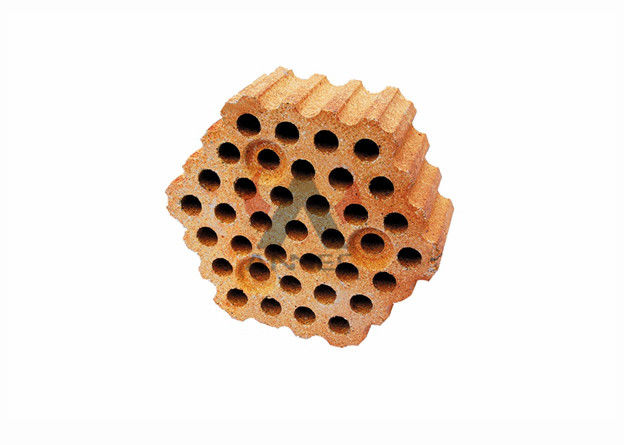

نقدم لكم طوب الطين الحراري عالي الجودة، المصمم لتلبية المتطلبات الصارمة لتطبيقات الأفران الصناعية. صُنعت هذه الطوب الحراري العازل من الطين بدقة وخبرة لتقديم أداء استثنائي في درجات الحرارة المرتفعة والظروف القاسية.

مع مقاومة ممتازة للأحماض، فإن طوب الأفران الطينية هذا مناسب تمامًا للبيئات التي توجد بها مركبات حمضية، مما يوفر حماية موثوقة ضد التآكل والتدهور. تضمن مقاومتهم الفائقة متانة وموثوقية تدوم طويلاً في مختلف البيئات الصناعية.

يفتخر طوب الطين الحراري الخاص بنا بحد أدنى لقوة السحق الانضغاطي (CCS) يبلغ ≥40 ميجا باسكال، مما يضمن بناءً قويًا ومتينًا يمكنه تحمل الأحمال الثقيلة والحرارة الشديدة. تعكس درجة CCS العالية هذه جودة وقوة هذه الطوب، مما يجعلها خيارًا يعتمد عليه للتطبيقات الهامة.

الحجم القياسي لهذه الطوب الطيني هو 230*114*73 ملم، مما يوفر خيارًا متعدد الاستخدامات لتبطين الأفران ومشاريع البناء. تضمن الأبعاد المتسقة والقياسات الدقيقة سهولة التركيب والتوافق مع الأفران الصناعية القياسية، مما يسهل العمليات السلسة والفعالة.

مع كثافة حجمية تتراوح من 2.1 إلى 2.2، يوفر طوب الأفران الطينية هذا خصائص عزل حراري مثالية مع الحفاظ على السلامة الهيكلية. تعمل الكثافة الحجمية المثالية لهذه الطوب على تحسين قدراتها على الاحتفاظ بالحرارة، مما يجعلها خيارًا فعالًا لبطانات الأفران وتطبيقات العزل.

مصمم للاستخدام كبطانات للأفران، يعتبر طوب الطين الحراري هذا حلاً موثوقًا به لحماية جدران وأرضيات الأفران من درجات الحرارة القصوى والتفاعلات الكيميائية. تركيبه وخصائصه تجعله مناسبًا لتحمل الحرارة الشديدة والدورات الحرارية الشائعة في عمليات الأفران الصناعية.

الميزات:

-

اسم المنتج: طوب طيني حراري

-

الكثافة الظاهرية: 2.1-2.2

-

معدل الزحف: ≥1350℃

-

الأصل: الصين

-

معامل الكسر: 70~80

-

التطبيق: فرن إعادة التسخين

المعايير الفنية:

|

مقاومة الصدمات الحرارية

|

جيد

|

|

الاستخدام

|

بطانة الفرن

|

|

معامل الكسر

|

70~80

|

|

الحجم

|

قياسي أو مخصص

|

|

درجة حرارة التليين

|

≥1280℃

|

|

التطبيق

|

فرن إعادة التسخين

|

|

الحجم القياسي

|

230*114*73 ملم

|

|

الكثافة الظاهرية

|

2.1-2.2

|

|

معدل الزحف

|

≥1350℃

|

|

التركيب الكيميائي

|

Al2O3: 30-45%، SiO2: 50-65%، Fe2O3: <2%

|

التطبيقات:

تعتبر طوب الطين الحراري مواد متعددة الاستخدامات وضرورية في مختلف التطبيقات الصناعية نظرًا لخصائصها الاستثنائية. مع تركيبة كيميائية تتكون عادةً من Al2O3 (الألومينا) التي تتراوح من 30% إلى 45%، وSiO2 (السيليكا) بين 50% إلى 65%، وFe2O3 (أكسيد الحديد) أقل من 2%، توفر هذه الطوب الطيني عالي الألومينا مقاومة ممتازة لدرجات الحرارة المرتفعة والبيئات القاسية.

يقع معامل الكسر لطوب الطين الحراري هذا ضمن نطاق 70 إلى 80، مما يدل على قوتها الفائقة وقدرتها على تحمل الإجهاد الميكانيكي. وهذا يجعلها مثالية للاستخدام كبطانة للفرن، حيث يمكنها احتواء وتحمل ظروف الحرارة الشديدة بشكل فعال دون المساس بالسلامة الهيكلية.

مع قوة سحق انضغاطي (CCS) تبلغ 40 ميجا باسكال على الأقل، توفر هذه الطوب متانة وموثوقية في ظل الضغط، مما يضمن أداءً طويل الأمد في البيئات الصناعية الصعبة.

متوفرة بأحجام قياسية وأبعاد مخصصة، يمكن تصميم طوب الطين الحراري لتناسب متطلبات وتصميمات أفران معينة، مما يوفر المرونة والدقة في مشاريع البناء.

تشمل مناسبات وسيناريوهات تطبيق المنتج الشائعة لهذه الطوب الطيني الحراري على سبيل المثال لا الحصر الأفران العالية وأفران صناعة الصلب وأفران الأسمنت وخزانات الزجاج والعمليات الصناعية الأخرى ذات درجة الحرارة العالية حيث يكون العزل الحراري والمقاومة الكيميائية أمرًا بالغ الأهمية.

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!  يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!